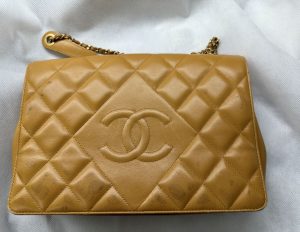

Leather is natural which from the beginning of the process reacts differently to nature’s elements, and some have less resistance due to how the hides were finished, unique to genuine leather, a product was not engineered. No two hides are exactly alike, as with all things in nature. Masters are contracted to bring the best to market, and most consumers know the sight, feel and smell of great leather.

Leather is natural which from the beginning of the process reacts differently to nature’s elements, and some have less resistance due to how the hides were finished, unique to genuine leather, a product was not engineered. No two hides are exactly alike, as with all things in nature. Masters are contracted to bring the best to market, and most consumers know the sight, feel and smell of great leather.

Being one of the strongest upholstery material used for furniture, it has proved to outlast all other fabric. Though leather is durable, between the top grain that retains the leathers’ natural ability to adjust to its environment, and how the consumer keeps the product safe from light, dirt, and general wear from surface temperature, leather can deteriorate. Its history is recorded in the grain, wrinkles, scratches and scars acquired. It is a valuable commodity. Minimal upkeep can extend leather’s life.

Processing, refinishing, and restoring leather these days is a modern science yet the science is an ancient form of art. In today’s competitive markets, leather production faces more demands than ever before, from other materials and consumer demand expecting better performance. Having the tannery background enables us to understand a variety of leather finishes needed to cover the gamut of leathers.

Important points:

- We refinish a leather product as close as possible to the actual finish.

- We do not over-spray the product.

- We take into consideration the age of older leather.

- We fully understand how to moisturize, restore and refinish with soft dyes and sealers.

- For worn leather bags and furniture, we first treat them by using softening product such as: resins, soft-binding agents to correct the damaged grains, scratches and scars. We repair them, and then we recolor and refinish them. We use air brushes for small, delicate jobs; and mini gun for large jobs.

- Some colors have good coverage characteristics, or properties, that require only 1 or 2 light coats of dye to finish it. These colors are black, navy, brown, gray, dark-green, beige, pink, camel, tan, etc… But others such as white, red, yellow, and green require more spraying coats.

- We seal the product with different type of soft and pleasant feel finishing.

- We have the ability to add some artistic nuances to the finish. By re coloring it in an antique look, we give it a cloudy, two-tone transparent color called aniline finishing.